Maintaining your John Deere tractor requires more than just fuel; the right coolant is crucial for engine longevity and overall performance. This guide provides a comprehensive approach to selecting, using, and disposing of coolant responsibly, aligning with sustainable agriculture practices. For information on other tractor fluids, check out this helpful resource on tractor hydraulic fluids.

Understanding Coolant Options

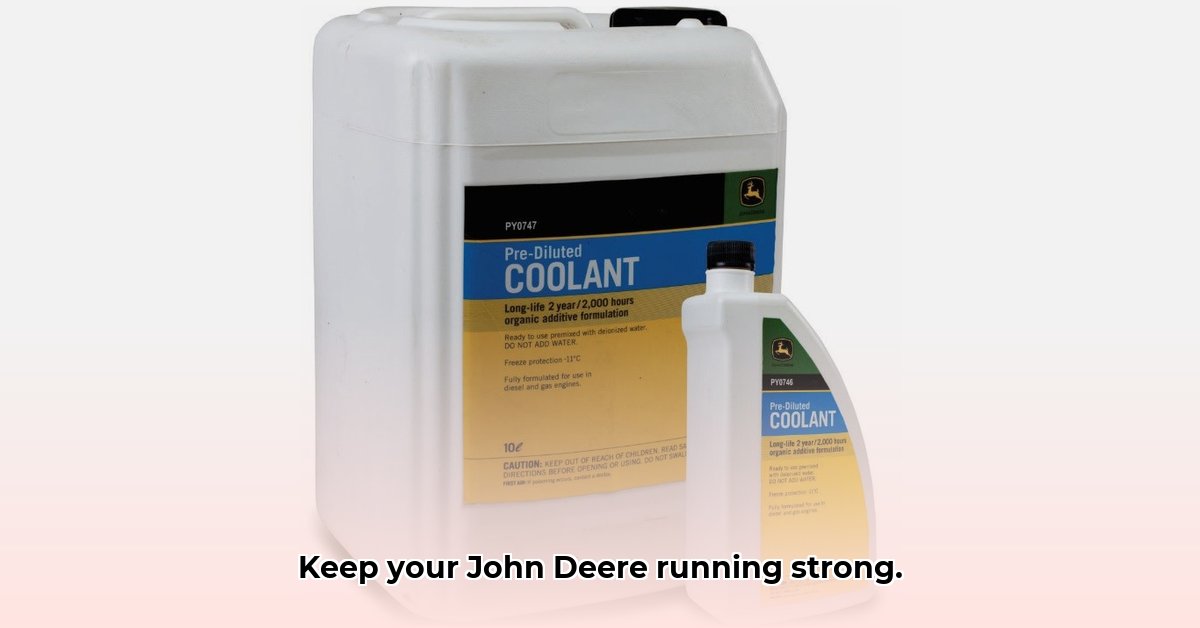

Choosing the right coolant for your John Deere tractor involves understanding the various types available. Each type possesses unique properties, influencing its performance and environmental impact. The most common coolants include ethylene glycol, propylene glycol, and extended-life coolants.

- Ethylene Glycol: This traditional coolant offers excellent cooling capabilities but is toxic and requires careful disposal. Improper handling can harm the environment.

- Propylene Glycol: A less toxic alternative to ethylene glycol, propylene glycol provides comparable cooling performance with a reduced environmental footprint.

- Extended-Life Coolants: Designed for longer service intervals, these coolants can reduce maintenance frequency but may come at a higher initial cost.

Which coolant is best for you? Your John Deere tractor's owner's manual provides specific recommendations based on your model and operating conditions. Always prioritize the manufacturer's guidelines to avoid potential damage and warranty issues. Ignoring these recommendations could lead to costly repairs. Do you need to ask yourself – is preventing costly repairs worth the time spent reviewing the manual?

Selecting the Right Coolant

The ideal coolant for your John Deere tractor depends on various factors. Climate significantly influences coolant choice, with hotter climates requiring coolants that can withstand higher temperatures and prevent overheating. Conversely, colder climates demand coolants that prevent freezing and potential engine block damage. The intensity of your tractor's use also impacts the appropriate coolant selection; more frequent and demanding use might benefit from the longer service life of extended-life coolants.

Your John Deere owner's manual is your primary resource. It outlines the specific coolant type, concentration, and other crucial details tailored to your tractor model and typical operating conditions. By using this resource, you ensure compatibility and safeguard your investment and warranty protection. Remember, using the wrong coolant can lead to irreversible engine damage and costly repairs.

Correct Coolant Mixing and Filling: A Step-by-Step Guide

Improper coolant mixing can severely impact the cooling system's efficiency. Always follow the manufacturer's instructions on coolant-to-water ratios (if applicable), using only distilled or deionized water. Tap water contains minerals that can accumulate, causing damage.

Steps to Proper Coolant Mixing and Filling:

- Consult your owner's manual: Determine the precise coolant-to-water ratio and filling procedure specific to your John Deere tractor model.

- Gather supplies: Ensure you have the correct coolant, distilled or deionized water, a funnel, and appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Mix carefully: Slowly add the coolant to the water, stirring gently to prevent splashing and ensure thorough mixing. Never add water directly to the coolant.

- Fill the radiator: Use the funnel to carefully pour the mixture into the radiator, avoiding spills. Ensure no air pockets remain.

- Check the overflow tank: Top off the overflow tank to the recommended level.

- Run the engine: Run the engine briefly to circulate the coolant and remove any remaining air pockets.

Coolant Maintenance and Testing: Preventative Measures

Regular coolant checks are essential for preventing costly repairs. These checks are just as important as routine oil changes. Consider these preventative measures:

- Coolant Level Check: Inspect coolant levels weekly or after every 10 hours of operation.

- Leak Inspection: Conduct a visual inspection for leaks monthly, addressing any issues promptly.

- Coolant Analysis: Undergo professional coolant analysis annually or every 2000 hours of operation to detect potential problems before they escalate. This analysis reveals any contaminants present.

Remember: Consistent maintenance is far less expensive than major repairs resulting from neglect.

Responsible Disposal: Protecting Our Environment

Used coolant is classified as hazardous waste due to its toxicity. Improper disposal contaminates soil and water sources, harming the environment.

Responsible disposal methods include:

- Recycling centers: Contact your local recycling center to inquire about used coolant disposal options. Many centers accept used automotive fluids.

- Hazardous waste facilities: Locate and utilize designated hazardous waste facilities for environmentally sound disposal.

- John Deere dealerships: Many dealerships offer coolant recycling services as part of their commitment to sustainable practices.

By responsibly disposing of used coolant, you actively contribute to a healthier environment and the success of sustainable agriculture. Remember, sustainable agriculture isn't just about crops; it's about responsible resource management across the board.